Welcome to Hamburger Containerboard Gelsenkirchen

Hamburger Containerboard Gelsenkirchen offers its European customers and partners a complete range of high-quality corrugated base papers, which is produced from 100% recovered paper. In Gelsenkirchen we currently have 163 qualified and motivated employees who take care of all aspects of paper. We can proudly claim to be the market and quality leader in Europe!

Your contact persons at location Gelsenkirchen

Tradition and innovative spirit

The Hamburg Containerboard first started papermaking in Germany at Trostberg, more than 100 years ago, originally under the name of the company founder: Rieger. From the production of handmade paperboard and cardboard, development became focused, over the decades and then with the acquisition by the Austrian based W. Hamburger AG (1989), on white testliners. Over the years RiegerLiner has become a brand name in its own right. The successful development and progress in this product segment then led to the construction of the new plant in Spremberg. The PM1 went into operation in 2005.

After the merger of both locations in 2010, Hamburg Containerboard was expanded in 2014 with the Papierfabrik (paper mill) in Gelsenkirchen. Today Hamburger Containerboard is the market leader in the field of coated and uncoated white testliners. The names of the original company founders, Wilhelm Hamburger (Pitten, Austria) and Johann Rieger (Trostberg, Germany), are retained to this day in the names of our companies.

The entrepreneurial vision and outstanding achievements of our company forefathers and the Prinzhorn family set a precedent for the continuous sustainable development of our company for the future, to which we are all bound. Through this we embody both Tradition - our shared experience and common value set - and Innovative Spirit - our capacity to innovate, develop new products and processes, and implement state-of-the-art machinery and systems. We do not see any contradiction here – on the contrary. Only those who are aware of their past and willing to learn from it are able to shape the future.

The combination of tradition and progress shapes our company history.

For decades, our cardboard and paper machines have been in reliable operation at locations such as Trostberg, Gelsenkirchen and Spremberg. Their long lifespan not only stands for technical consistency, but also for the continuous development of our know-how.

“Passion for Paper. Since 1853.”- Is not just a guiding principle. It is a living reality: then, now and for the future.

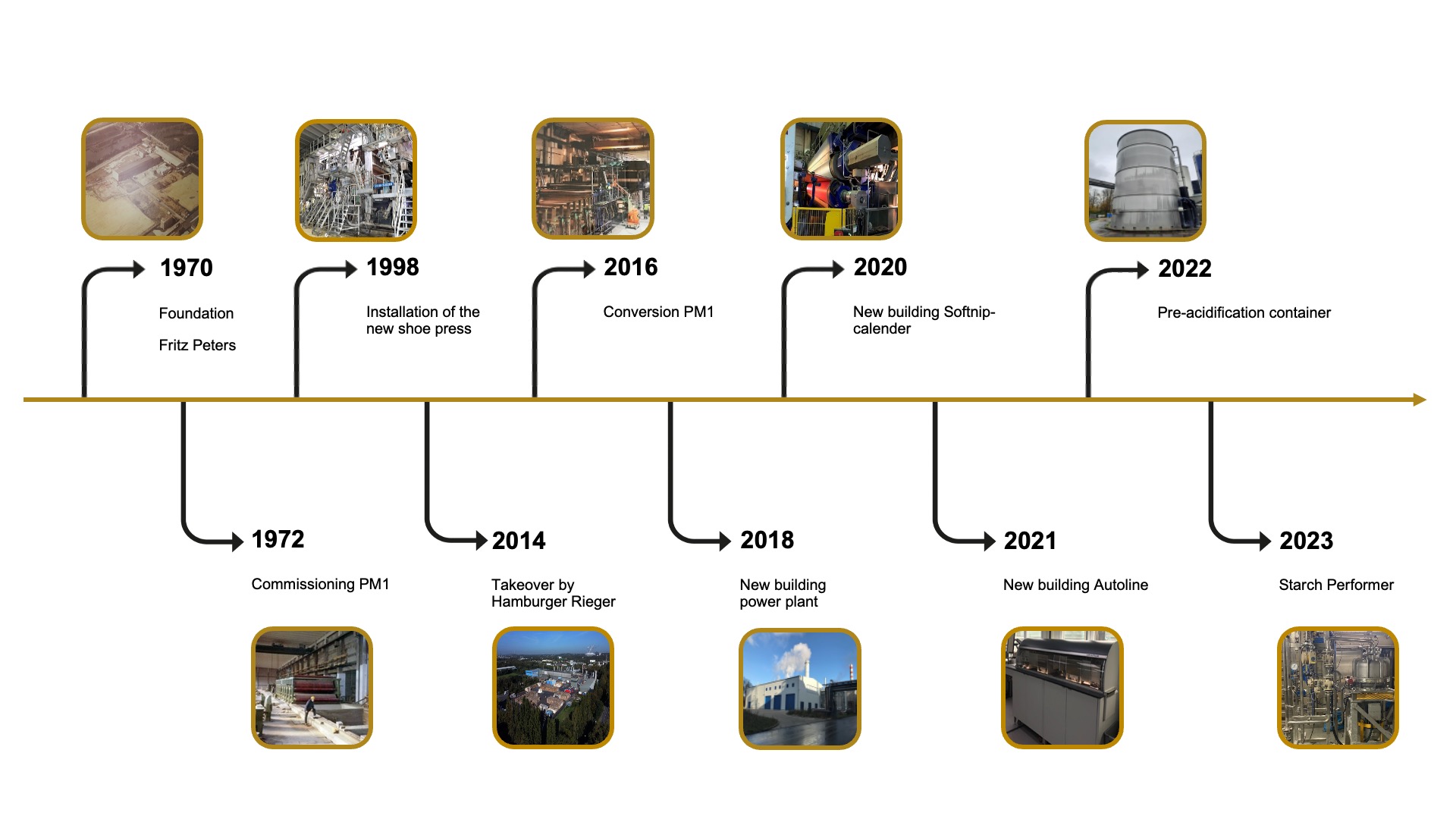

History of the Gelsenkirchen location

| 2023 | Starch Performer |

| 2022 | Pre-acidification container |

| 2021 | New construction Autoline |

| 2020 | Construction of new soft nip calender |

| 2018 | Construction of new power plant |

| 2016 | Modification of the PM1 |

| 2014 | Acquisition of Papierfabrik Gelsenkirchen by Hamburger Rieger Group |

| 2012 | Certification to the FSC standard, launch of implementation of integrated management system and introduction of DIN EN ISO 50001 |

| 2011 | Construction and commissioning of floatation plant for water pre-treatment in the inlet to the biological cycle water treatment plant |

| 2010 | Construction of a biological cycle water treatment plant with CHP to clean the cycle tanks and reduce water consumption and waste water pollution |

Performance Data

Paper machine 1

| Production | 253,000 tonnes/year |

| Working width | 505 cm |

| Operational speed | 960 m/min. |

| Grammage | 120 bis 235 g/m2 |

| Products | White faced testliner, gypsum grade liner board, brown testliner |

Machine features:

- Fourdrinier machine with top screen

- 6 double row dryer groups

- Implemented film press

- 2 slalom dryer groups

- Soft-Nip calender

- Fully automatic Metso WinDrum roll cutter

Factory Safety

The health and physical safety of our employees and visitors are of utmost importance to us.

People are central to our operation, so occupational safety takes the utmost priority!

For this reason, it is essential that all the rules and regulations that we have compiled here are strictly observed and adhered to. This equally applies to the applicable accident prevention regulations, all valid laws and statutory regulations, regulations stipulated by trade associations, and the rules and information as well as all signage in the factory.

All these rules and regulations apply to our permanent staff as well as by analogy to any visitors, external and temporary workers, installation personal and transport company drivers.

Please always work and act safely and conduct yourself in such a manner that accidents and injuries are avoided. Our target is zero accidents.

But order and cleanliness are also a part of safety!

Any activity, regardless of its nature, is only considered to have ended when the working environment has been tidied up and cleaned properly and all tools and consumables have been properly returned or stored in the designated places.

Plant and equipment must be left or handed over in accordance with regulations. Within these activities, special rules, for example with materials handling equipment (forklifts, hi-reach platforms, cranes, etc.) must be adhered to.

If you notice any work being improperly executed, or see hazards or other deviations from the regulations described here, you are obliged to report this to your supervisor or the contact person responsible for you in the company.

Take personal responsibility for tidiness and cleanliness by leaving your workplace and work environment in a good state.

Through your diligence and cooperation, you create the basis for orderly, smooth, safe and successful work.

At our location in Gelsenkirchen we are on the right track, and have significantly reduced the number of accidents in recent years. We focus on open communication, because knowledge helps to avoid risks and thus accidents.

We thank you for your support!

Information for external companies

Here you will find important information and special regulations for external companies that must be observed when working on the premises of Hamburger Rieger Gelsenkirchen GmbH & Co KG: