Hamburger Containerboard Spremberg

Hamburger Rieger GmbH, Paper mill Spremberg

An der Heide B5

03130 Spremberg

Germany

Phone: +49 3564 378-0

Fax: +49 3564 378-21090

Email: office.spr(at)hamburger-containerboard.com

More information about Spreerecycling GmbH & Co. KG

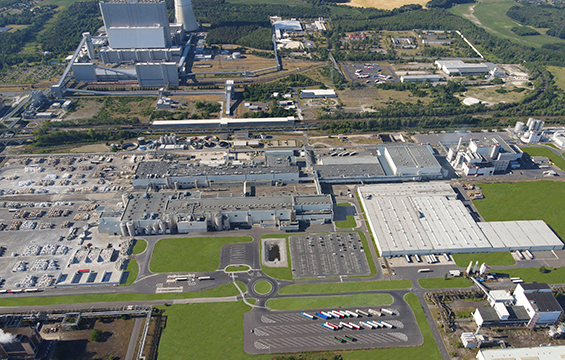

About Hamburger Containerboard Spremberg

With approximately 485 employees, Hamburger Conntainerboard in Spremberg is one of the largest employers in the region.

In addition to the production of white uncoated corrugated containerboard, we also produce high-quality white coated papers under the RiegerCoat Economic name. The portfolio is rounded off by the production of various gypsum-grade paperboard types.

Tradition and modernity

The history of papermaking in Spremberg began in 2003 with Thomas Prinzhorn's decision to build a paper machine in the Schwarze Pumpe industrial park. The festive inauguration of the paper factory followed in 2005.

Starting in 2009, 100% white uncoated base paper was produced at the Spremberg site. With a keen eye for the development of the market, the need for white coated paper was recognised early on and the company invested in a coating system, which was put into operation in 2015.

We received the biggest honour for the Hamburger Containerboard in Spremberg in 2018 from our owner, Mr. Prinzhorn, with the announcement and ground-breaking ceremony for the construction of the second paper machine.

The outstanding performance and entrepreneurial vision of the Prinzhorn family spurs us on to continue a sustainable advancement of our company. We rely on "tradition" (experience, common value system), but also on "modernity" (innovative strength, new products and processes, state-of-the-art machines and systems). We do not see any contradiction here – on the contrary. Only those who are aware of "their" past and willing to learn from it are able to shape the future.

History of Hamburger Containerboard Spremberg

| 2024 | Installation of the first boiler support for the power plant expansion, awarded the Brandenburg apprenticeship award |

| 2020 | Commissioning of Paper Machine 2 |

| 2018 | Construction start of Paper Machine 2 |

| 2015 | Commissioning of the coating line, 10-year anniversary celebration |

| 2014 | Fusion of Hamburger Containerboard Gelsenkirchen |

| 2013 | Continuous permanent operation of the refuse-derived fuel power plant, expansion of the waste paper storage area put into operation |

| 2012 | Successful boiler pressure test at Spreerecycling, Spreerecycling begins scheduled trial operation of the power plant |

| 2011 | Film press conversion, first time producing more than 20,000 tons of gypsum-grade paperboard, new roll packaging line |

| 2010 | Fusion of Hamburger Containerboard Trostberg with Hamburger Containerboard Spremberg |

| 2009 | Conversion to 100% white papers, press conference for the power plant |

| 2008 | Awarded the Brandenburg apprenticeship award, approval notice for the power plant, start of production of gypsum-grade paperboard |

| 2006 | Annual ISO certification since 2006 |

| 2005 | Inauguration of Paper Machine 1 |

| 2004 | Topping-out ceremony, trial operation of Paper Machine 1 |

| 2003 | Groundbreaking ceremony of Paper Machine 1 |

Performance data

Paper machine 1

| Production | 330,000 tons/year |

| Working width | 530 cm |

| Operating speed | 1,200 m/min |

| Grammage | 120 to 180 g/m2 |

| Products | White coated and uncoated Testliner, Plasterboardliner |

Machine features:

- Gapformer, 2 fourdrinier wires, dilution water control

- Press section designed for smoothness

- Film press (pigmentation, precoating)

- 2 calenders

- QLS/PLS, on-line colour measurement

- Line inspection system

- Fully automatic reel cutter with dust extraction

- Automatic reel packaging system

Paper machine 2

| Production | 495,000 tons/year |

| Working width | 780 cm |

| Operating speed | 1,250 m/min |

| Grammage | 90 to 180 g/m2 |

| Products | White Testliner, Brown Testliner |

Machine features:

- Stock preparation with deinking

- 1 gapformer, 1 fourdrinier wire

- Press section designed for smoothness

- Film press (pigmentation)

- softnip calender

- QLS

- Line inspection system

- Fully automatic reel cutter with dust extraction

Factory Safety

The health and physical safety of our employees and visitors are of utmost importance to us.

People are central to our operation, so occupational safety takes the utmost priority!

For this reason, it is essential that all the rules and regulations that we have compiled here are strictly observed and adhered to. This equally applies to the applicable accident prevention regulations, all valid laws and statutory regulations, regulations stipulated by trade associations, and the rules and information as well as all signage in the factory.

All these rules and regulations apply to our permanent staff as well as by analogy to any visitors, external and temporary workers, installation personal and transport company drivers.

Please always work and act safely and conduct yourself in such a manner that accidents and injuries are avoided. Our target is zero accidents.

But order and cleanliness are also a part of safety!

Any activity, regardless of its nature, is only considered to have ended when the working environment has been tidied up and cleaned properly and all tools and consumables have been properly returned or stored in the designated places.

Plant and equipment must be left or handed over in accordance with regulations. Within these activities, special rules, for example with materials handling equipment (forklifts, hi-reach platforms, cranes, etc.) must be adhered to.

If you notice any work being improperly executed, or see hazards or other deviations from the regulations described here, you are obliged to report this to your supervisor or the contact person responsible for you in the company.

Take personal responsibility for tidiness and cleanliness by leaving your workplace and work environment in a good state.

Through your diligence and cooperation, you create the basis for orderly, smooth, safe and successful work.

At our location in Gelsenkirchen we are on the right track, and have significantly reduced the number of accidents in recent years. We focus on open communication, because knowledge helps to avoid risks and thus accidents.

We thank you for your support!

Information for external companies

Here you will find important information and special regulations for external companies that must be observed when working on the premises of Hamburger Rieger Gelsenkirchen GmbH & Co KG: